9 Mistakes To Avoid When Using ICF Blocks

ICF Installation doesn't need to be costly. read this and avoid the 9 most common mistakes

Buildings using Insulated Concrete Forms (ICF) has become a common practice. This increase in popularity is because of the benefits these materials offer, notably better insulation, durability, and stability. However, some builders don't enjoy these benefits because they make mistakes when installing these materials.

The common mistakes to avoid when using ICF blocks are working without a guide, failing to do a thorough pre-pour inspection, using the wrong concrete mix, using too many cantilevers, poor choice of bracing and alignment systems, ignoring uthe roofline, failing to do proper research, and poor teamwork.

This article will explain the mistakes mentioned above in detail. Read on to learn more about how to avoid them and the steps to follow when installing ICF blocks.

9 Mistakes To Avoid When Using ICF Blocks

- Working Without a Guide

- Failure To Do a Thorough Pre-Pour Inspection

- Poor Coordination When Pouring Concrete

- Using the Wrong Concrete Mix

- Not Using Enough Fasteners

- Ignoring the Roofline

- Excessive Use of Cantilevers

- Poor Choice of Bracing and Alignment Systems

- Failure To Do Proper Research

This article will explain the mistakes mentioned above in detail. Read on to learn more about how to avoid them and the steps to follow when installing ICF blocks.

Insulated Concrete Forms

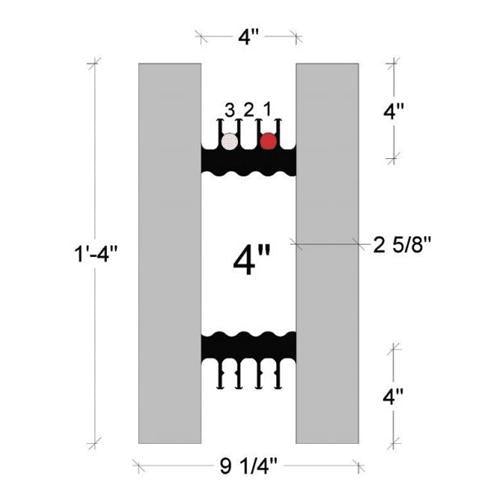

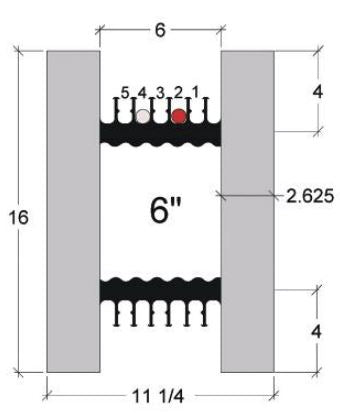

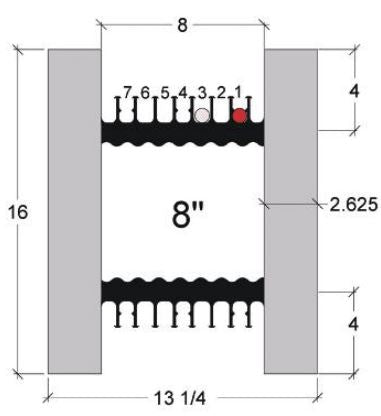

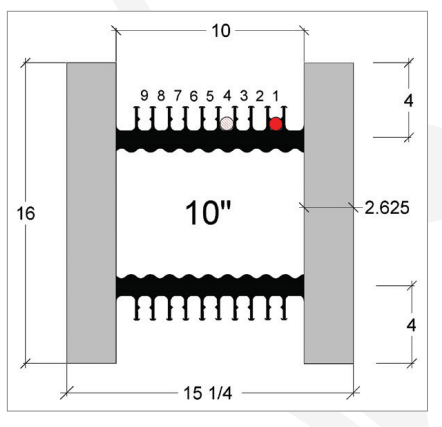

Fox Blocks range from 4" to 12" wide walls

1. Working Without a Guide

It would help if you never underestimated the challenges your engineering and construction team will face when installing ICF walls. It is essential to have a design guide that your team will follow during installation.

Your design guide should be reliable – it should contain crucial information on the areas that need reinforcement. Besides, a guide specifies the appropriate materials required to construct a stronger and more durable building.

2. Failure To Do a Thorough Pre-Pour Inspection

Failing to do a thorough pre-pour inspection can be costly. Therefore, you should inspect the forms the day before the pour. By doing so, you avoid casting mistakes, which could compromise your building's structural integrity.

You should do the following during the pre-pour inspection:

- Inspect the forms as soon as they are delivered to you. Ensure none have been damaged during transit.

- Ensure that all vertical seams, block cuts, and openings are braced and strapped correctly.

- Check that all blocks are correctly stacked and firmly seated.

- Ensure that rebars are of the required quality.

PRO TIP: Handle the ICF Bundles carefully. Rolling or throwing units can reduce interlocking capacity of EPS Forms

3. Poor Coordination When Pouring Concrete

Poor teamwork can lead to avoidable mistakes when using ICF. Specifically, poor communication between your crew's members can result in using high or low slump concrete, errors during casting, and failure to effectively identify and address challenges.

You should emphasize proper communication and assign different roles to your construction team.

- Checking the concrete slump.

- Inspecting openings, adjusting bracings, and leveling concrete.

- Setting anchor bolts.

- Cleaning the site after the pour.

The team should be conversant with your goals. They should also communicate any issues that need to be addressed.

4. Using the Wrong Concrete Mix

A poor concrete mix can be detrimental to your walls. Notably, the mix determines the strength and pressure your walls exert on the foundation. Therefore, using the wrong mix can compromise the entire structure's stability.

To ensure that you have the right concrete mix, you should perform the slump test. For that, you need a tape measure, a tamping rod, and an Abrams cone. The procedure for performing this test is as follows:

- Fill the cone with fresh concrete and tamp it 25 times. Repeat this procedure three times to consolidate the concrete.

- At the end of the third stage, level the concrete with the top of the cone.

- Lift the cone carefully, ensuring that the concrete settles naturally.

- Place the upturned cone on the base as a reference, and measure the distance between the top of the cone and the top of the concrete to the nearest 10mm (0.0328 ft).

You can watch this video for a brief tutorial on how to perform this test:

Note: The US Department of Housing and Urban Development recommends a slump of 4ft-6ft (121.9cm – 182.9cm).

5. Not Using Enough Fasteners

Sometimes, builders cannot resist the urge to complete their projects in time. When you are in such a situation, you may be tempted to use fewer fasteners to speed the process. However, this hurts the durability of the completed project. Also, you may end up spending on premature repairs.

It is vital to use the right number of fasteners on the interiors and exteriors. Also, use the recommended ones based on your ICFS. You should use self-tapping screws for metal-webbed ICFS and sharp, coarse-threaded screws for plastic-webbed ICFs.

Consult an expert to help you determine the ideal fasteners to use if unsure. Also, note that some ring nails and screws are better for fastening the interior than the exterior.

6. Ignoring the Roofline

You want to enjoy the thermal efficiency that ICF construction offers? Right? Then, it would be best if you never went wrong on the roofline.

Leaving a gap between the roof, the air barrier, and the insulation is the most common mistake builders make in this regard. You should pay keen attention to the roof during the installation process to avoid lapses that could result in such gaps.

7. Excessive Use of Cantilevers

Did you know that ICF construction is more suitable for simple, conventional wall designs? When you add cantilevers to your structure, you complicate the design. Notably, cantilevers add more load to the walls, hurting your building's stability. Cantilevers are a feature in modern architecture and home building, however, using them in excess can add unnecessary complexity to your project

picture from

8. Poor Choice of Bracing and Alignment Systems

As a builder, you may be tempted to give your house a unique look. This drive may motivate you to design unique bracing and alignment systems.

However, your preferences may end up detrimental to your project. Notably, the systems you select may not produce a level and straight walls. Because of that, you may need to repair the walls.

Consequently, the wrong bracing and alignment systems can increase construction costs. Therefore, we recommend that you consult an expert before choosing these systems.

9. Failure To Do Proper Research

Unless you have previous experience of using ICF, you are likely to make several rookie mistakes when installing them. For this reason, you should arm yourself with as much information as possible.

Doing proper research enables you to determine the right types of forms to use and the mistakes to avoid when using ICF blocks. Also, it helps you identify the best supplier of materials.

This video describes some of the mistakes builders make when using ICF:

Final Thoughts

Due to their benefits, ICF blocks have become popular construction materials. Specifically, using ICF gives your house better insulation, stability, and makes it more durable. However, you must follow the right procedure during installation to enjoy these benefits.

To avoid the mistakes mentioned above, use a working guide, do a thorough pre-pour inspection, emphasize effective communication in your crew, use the right mix of concrete, and use enough fasters.

Also pay attention to the roofline, avoid using cantilevers, choose the right bracing and alignment systems, and do proper research. For better results, consult a reputable supplier and hire professionals.

Sources:

- US Department of Housing and Urban Development: Insulating Concrete Forms for Residential Construction: Demonstration Homes

- Concrete: Slump Test

- BuildBlock: Top 5 Ways to Ensure a Successful ICF Pour

- YouTube: ICF Home Build Mistakes And Wasting Money!!

- YouTube: Concrete Slump Test Tutorial

- DoItYourself: Installing Insulated Concrete Forms Step-By-Step

- The Portland Cement Association: Insulating Concrete Forms (ICF)

- Building Design + Construction: 13 Tips On Working With Insulating Concrete Forms