ITC 100 HT Ceramic Refractory Coating for Forge or Furnace

ITC 100 HT product is a high-temperature coating with a rating of up to 5000°F that has been shown to provide exceptional refractory protection and energy savings. The coating is utilized as a covering for refractory brick, castable, or ceramic fiber insulation. In particular, this is used in forges, kilns, and furnaces. For kilns, it minimizes glaze sticking.

NOT suitable for food-grade applications such as pizza ovens.

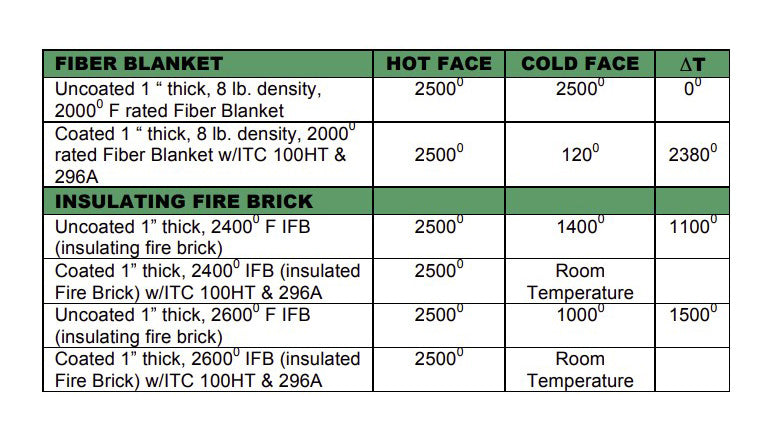

ITC-100 treatment coatings typically equate to one inch of insulation.

Available in Pint, 1-gallon, & 5-gallon sizes

This coating reflects radiant heat back into the furnace to reduce heat loss. The refractory capability saves money by retaining heat inside of the kiln and takes less fuel to operate and less time to achieve a high temperature of 4000-5000 degrees Fahrenheit.

Usage: 100HT can be used by itself or as a base coat, depending on the application, and used over castable refractory or ceramic fiber-lined furnaces.

- Reflectivity occurs around 900*F and becomes more efficient until the maximum temperature is achieved.

- Coverage: 6-12 square feet/pint

- Rated for up to 5,000 degrees F

- Save up to 60% on energy heating costs

100HT Pint Container Usage rates by application:

- Fiber Lining: 5 square feet

- Brick Lining IFB (Insulating Fire Brick): 10 square feet

- Brick Lining or Hard Cast Refractory: 6-12.5 square feet

FREE SHIPPING

Looking for a quote for your project? (800) 567-5358

Project Quote Form Here>